Contact Us

Hebei Headquarters

Tel:+86-316-5758058

Email:sales@kessolidscontrol.com

Hotline:+86-400-999-3630

Address: Industrial Road 2, Chaobai River Industrial Zone, Dachang County, Langfang City, Hebei Province

Xi'an Branch

Tel:+86-29-81717939

Fax: +86-29-86613026

Email:sales@kessolidscontrol.com

Hotline:+86-400-999-3630

Address: No.3 Fengcheng, Fengcheng No.3 Road, Weiyang District, Xi'an City, Shaanxi Province

Shale shaker is the first phase solids control equipment in oil drilling mud solids control system and the important equipment in the mud recycling system as well. Generally, there are single shale shaker, duplex shale shaker and triple shale shaker. KES can provide the shale shaker in different treatment capacity with customized service as per clients requirement.

The negative pressure shale shaker can improve the recycling of drilling mud by a unit of vacuum absorption device installed under the last screen of shaker, which can generate a certain frequency vacuum suction by pulsating air flow. This type shaker lowers the difficulty of mixed solid-liquid separation, effectively decreases the moisture content of solid phase of treated drilling cuttings by 20%~30%, increases the overall drilling efficiency, greatly reduces the drilling waste volume, thereby lowers the cost of waste treatment.

Vacuum degasser, also called Negative Pressure Degasser, is a special solids control equipment to handle the gas cut drilling fluid, removes the small bubbles entrained gas left in the mud and plays an important role to return mud proportion and stabilize mud performance. Generally, vacuum degasser is also matched with mud/slurry recycling purification systems.

Mud Cleaner is the second phase or the third phase solids control equipment, and it is a combination of desander, desilter and underneath shale shaker with the features of compact structure, small footprint and high efficiency. It is an ideal equipment as the second or the third phase solids control equipment. The shaker has linear and elliptical motion model at your option.

Desander is the second phase solids control equipment in drilling operation. Generally, there are a set of hydrocyclones in 8”, 10”or 12”in the desander, which mainly used for separating the solid particles sized in 47~76μm from the drilling fluids. The desander cleaner mainly consists of shale shaker, hydrocyclones, distribution manifold and electric control cabinet. Desander is used for removing the abrasive solids from the drilling fluids which cannot be removed by shale shaker. The shaker has linear and elliptical motion model at your option.

Desilter is the third phase solids control equipment to handle the drilling fluids. Generally, there are a set of hydrocyclones in 4”or 6”in the desilter, which mainly used for separating the solid particles sized in 15~47μm from the drilling fluids.

The desilter cleaner mainly consists of shale shaker, hydrocyclones, distribution manifold, and electric control cabinet. Desilter removes the solid particles from the drilling fluids which cannot be removed by shale shaker and desander. The shaker has linear and elliptical motion model at your option.

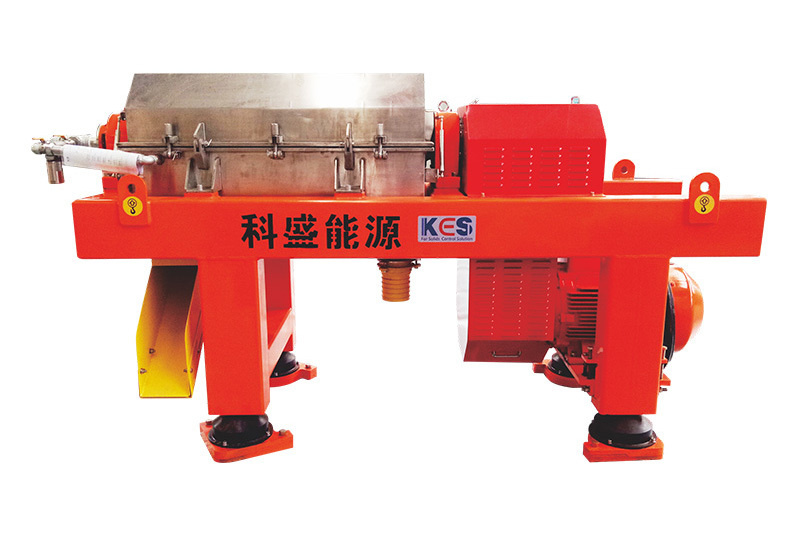

Decanter centrifuge is the fourth phase solids control equipment, also called Horizontal Spiral Centrifuge, Horizontal Decanter Centrifuge and Screw Decanter Centrifuge etc. According to different rotating speed, it can be defined as middle speed, high speed and high speed VFD centrifuge. It is mainly use for recycling the barite, removing the fine solid particles sized in 2-7μm, controlling the density and viscosity of drilling fluid to keep the drilling fluid performance, KES provides the customized centrifuge.

Vertical cutting dryer, also called as rock cutting dryer or vertical centrifuge, is the key equipment in drilling waste management system and widely used for handling the drilling cuttings in oil drilling field. For water-base drilling mud, KES cutting dryer also can achieve the ideal treatment effect.

Mud Gas Separator is a special equipment to handle the invaded gas of the drilling fluid. Density and viscosity of the drilling fluid will greatly be influenced by the invaded gas, sometimes it will lead to well kick or blowout accident.

Flare ignition device is a special oil drilling equipment to handle the invaded gas, it is also an effective equipment to handle the tail gas and invaded natural gas in oil field, refinery and natural gas collecting and distributing station. It can ignite the harmful invaded gas to eliminate the hazards to the environment, also it is a security environmental protection equipment. This equipment can match with mud gas separator, and is usually used in oil & gas drilling and CBM drilling project.

Jet mud mixer (Mud mixing hopper) is the equipment to match with the drilling solids control equipment, generally used for mixing and adjusting the proportion of drilling fluid, changing the density, viscosity and water loss etc. with more excellent operation if being matched with shear pump, and also can be designed to single or double jet mud

mixer as the clients requirements.

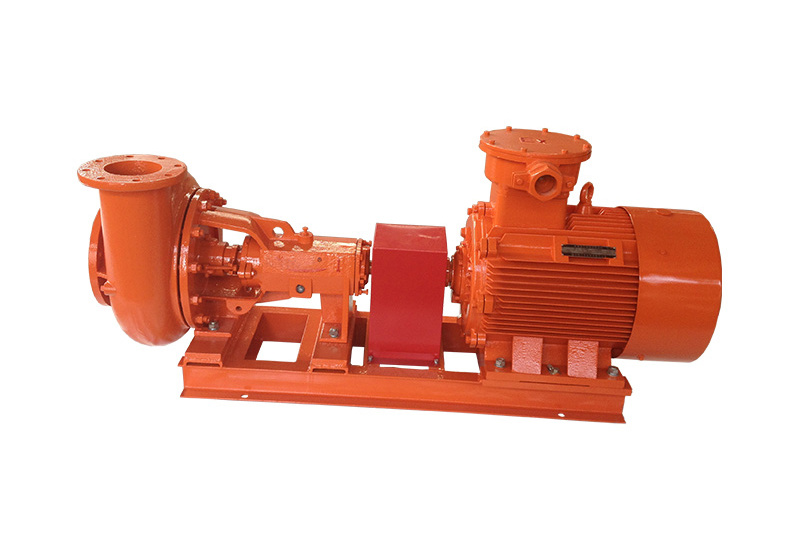

Centrifugal pump is also called as sand pump,mixing pump, feeding pump, replenishing pump and filling pump. It is the ideal matching equipment to provide impetus for desander, desilter and Jet mud mixer. Centrifugal pump can also be an assistant mud infusion pump and trip pump at well head. KES centrifugal pump can realize the quick positioning and installation.